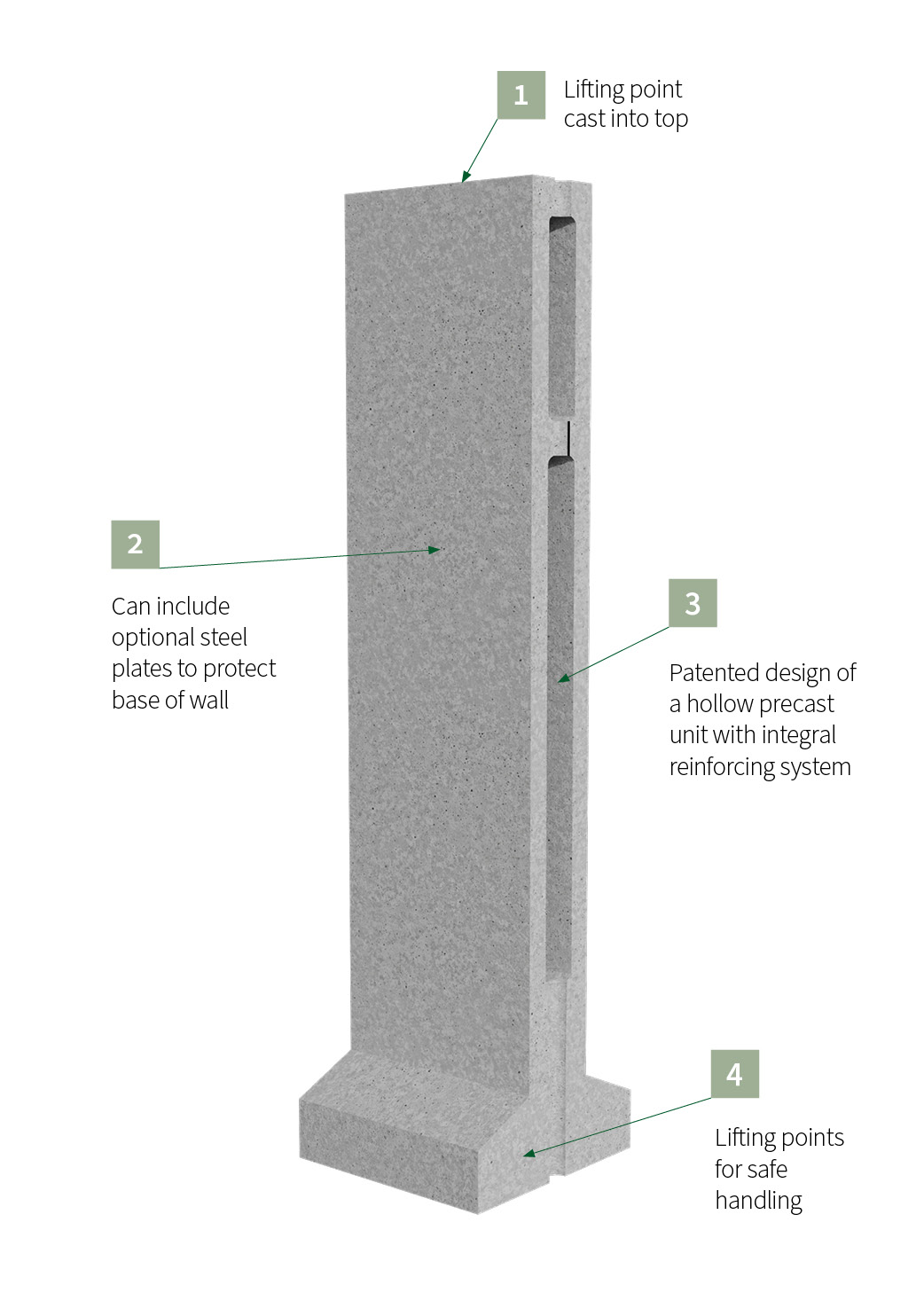

Shuttabloc™ precast concrete retaining wall

Poundfield's unique Shuttabloc™ precast concrete retaining wall system with internal reinforcing system has been designed to provide a faster, more economical alternative to casting in situ.

Up to 50% reduction in build time compared to full on-site construction More economical than casting walls in-situ Suitable for high spec walls that need to withstand impact or retain severe loads Only requires a concrete footing

Get in touch Fact sheet

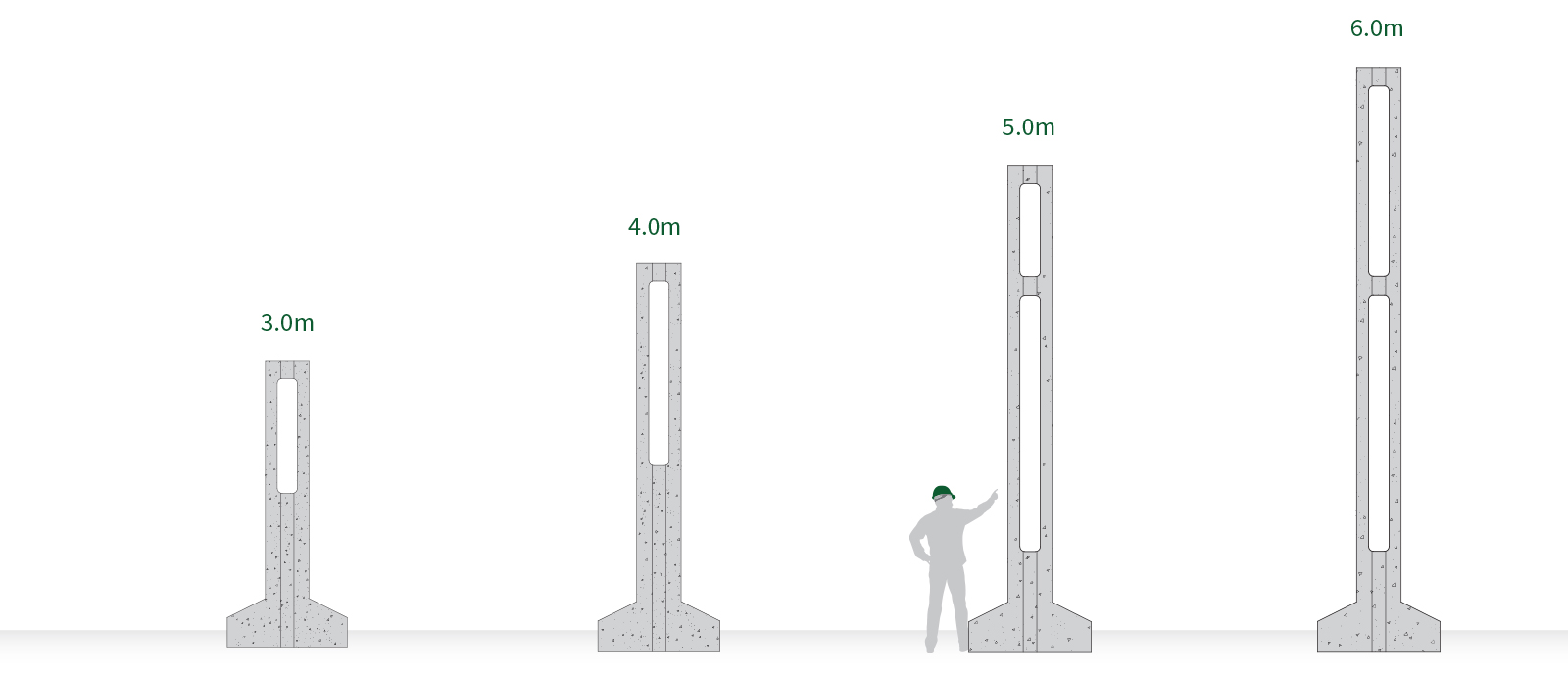

Sizes of the Shuttabloc™ concrete precast retaining wall

The hollow cores of the precast concrete units are pumped full of concrete once in place resulting in a solid push wall and can be designed and manufactured in a variety of heights (from 3m to 6m tall) and lengths tailored to suit your needs.

| Height | 3000mm | 4000mm | 5000mm | 6000mm |

| Length | 1220mm | 1220mm | 1220mm | 1220mm |

| Depth | 457mm | 457mm | 457mm | 457mm |

| Weight | 4.20 tonnes | 5.50 tonnes | 6.20 tonnes | 7.10 tonnes |

Watch our Shuttabloc™ explainer & installation video

Examples of the Shuttabloc™ in use

No on-site formwork, faster installation and a factory controlled finish results in a product that is flexible, cost-effective and designed to exactly the same properties as an in situ wall.

We can also supply a range of accessories to be used in conjunction with your wall to maximise its uses: Corner units to achieve a gap-free wall, T-junctions to create bays, and end covers to seal the wall units and finish off the ends.

We supplied Shuttabloc™ to some of the UK’s largest companies