Betaloc® precast concrete interlocking building blocks

The Betaloc® is Poundfield Precast's concrete brick style of interlocking building blocks, which provides a highly flexible construction system.

Ideal retaining wall system Rapid and flexible construction Permanent and temporary applications Expandable and moveable

Get in touch Fact sheet

Interlocking concrete blocks size

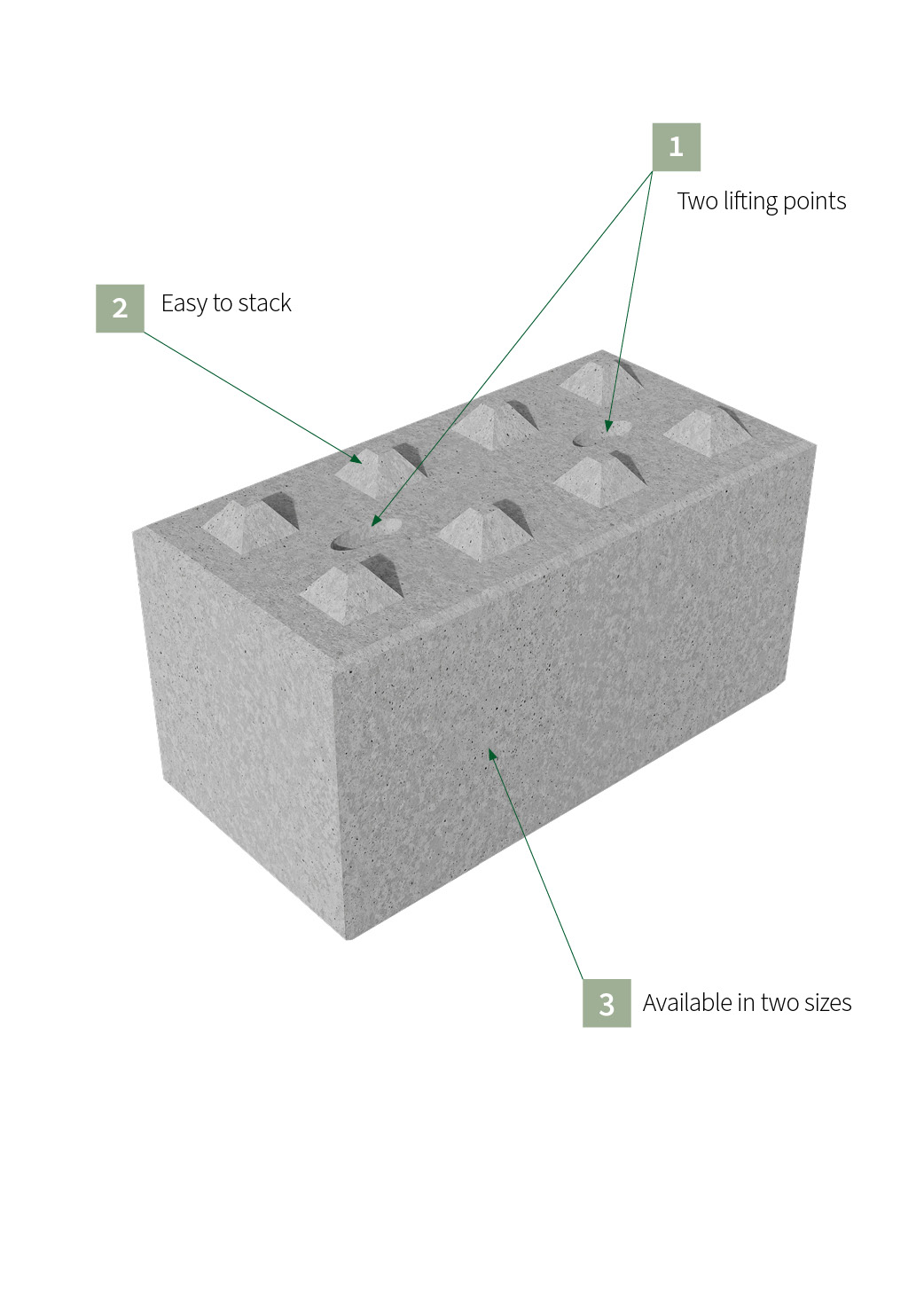

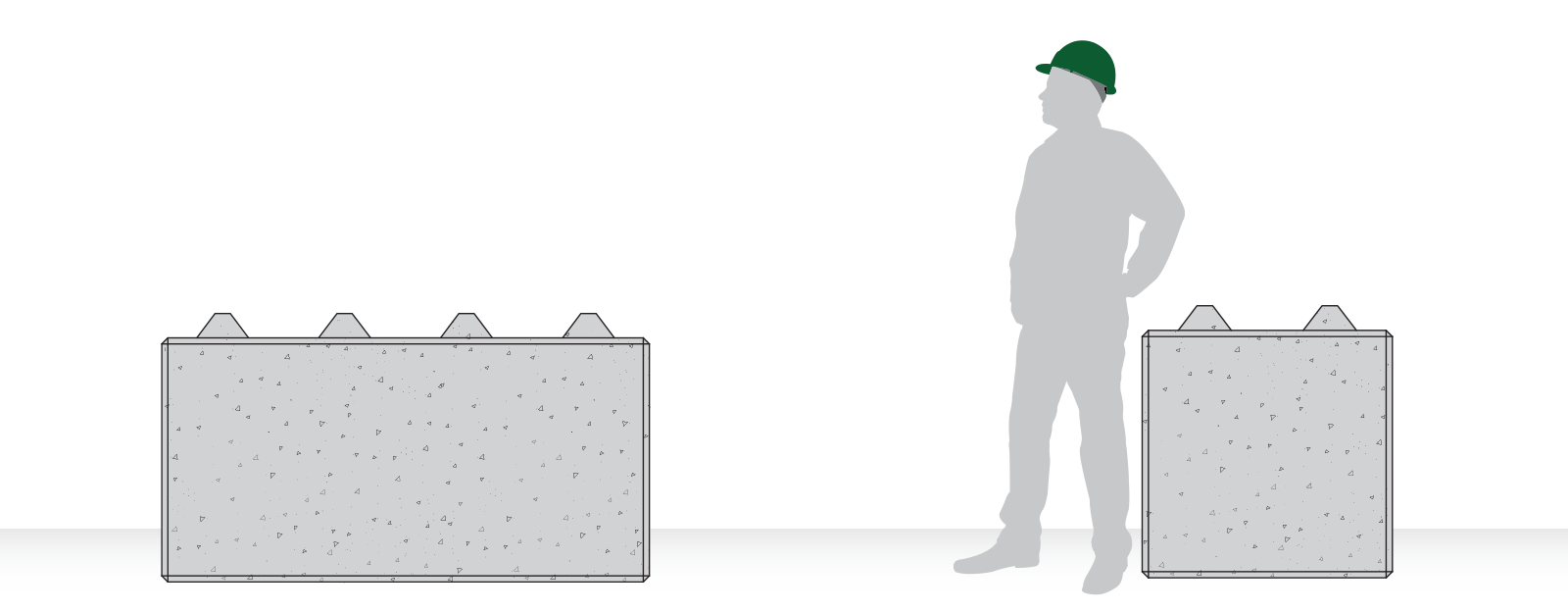

Our standard Betaloc unit is 800 x 800 x 1,600 mm long, made of solid precast concrete and weighs approximately 2.4 tonnes. With 2 lifting points the units are quick and easy to install, thanks to the stacking design of the units provided by an interlocking system. We also produce a half unit allowing for a flush finish to your walling, if required, which is 800mm in length.

We recommend a maximum height of 3-4 bricks dependent on use.

| Height | 800mm | 800mm |

| Length | 1600mm | 800mm |

| Depth | 800mm | 800mm |

| Weight | 2.40 tonnes | 1.20 tonnes |

Betaloc®- interlocking concrete blocks

If you’re looking for a flexible and cost effective way to create storage bays then look no further then our Betaloc blocks. Ideal for both temporary and permanent structures these interlocking precast concrete blocks are easy to stack, move and relocate. This flexibility makes them perfect for constructing storage areas, partition walls, perimeter or retaining walls, or to use in areas such as landscaping, flood defences or site security barriers.

These concrete blocks feature an interlocking design, with projections and depressions that allow them to fit neatly into the adjacent block, creating a secure and stable structure. The interlocking system ensures easy alignment both horizontally and vertically, making them simple to install without requiring specialised skills or equipment. They are specifically designed to lock together without the need for cement mortar or adhesives to bond them.

The interlocking blocks each weigh 2.4 tonnes and are simply laid on top of each other and are held in position by the interlocking lugs. With two cast-in lifting points, the units are quick to install and once in place the wall is immediately ready for use. The only real requirement prior to installation is to have a sound and level base.

We supplied Betaloc® to some of the UK’s largest companies