Beam & block flooring: our beams

Our precast concrete beams are suitable for use in a number of building projects, from one off properties to multi-million pound developments.

Poundfield beams are made from a precision steel mould using pre-stressed steel wires covered in a bespoke concrete design to give a high quality product, this process enables Poundfield to have a superior finish to other suppliers known as Wet-Cast finish or A-Grade.

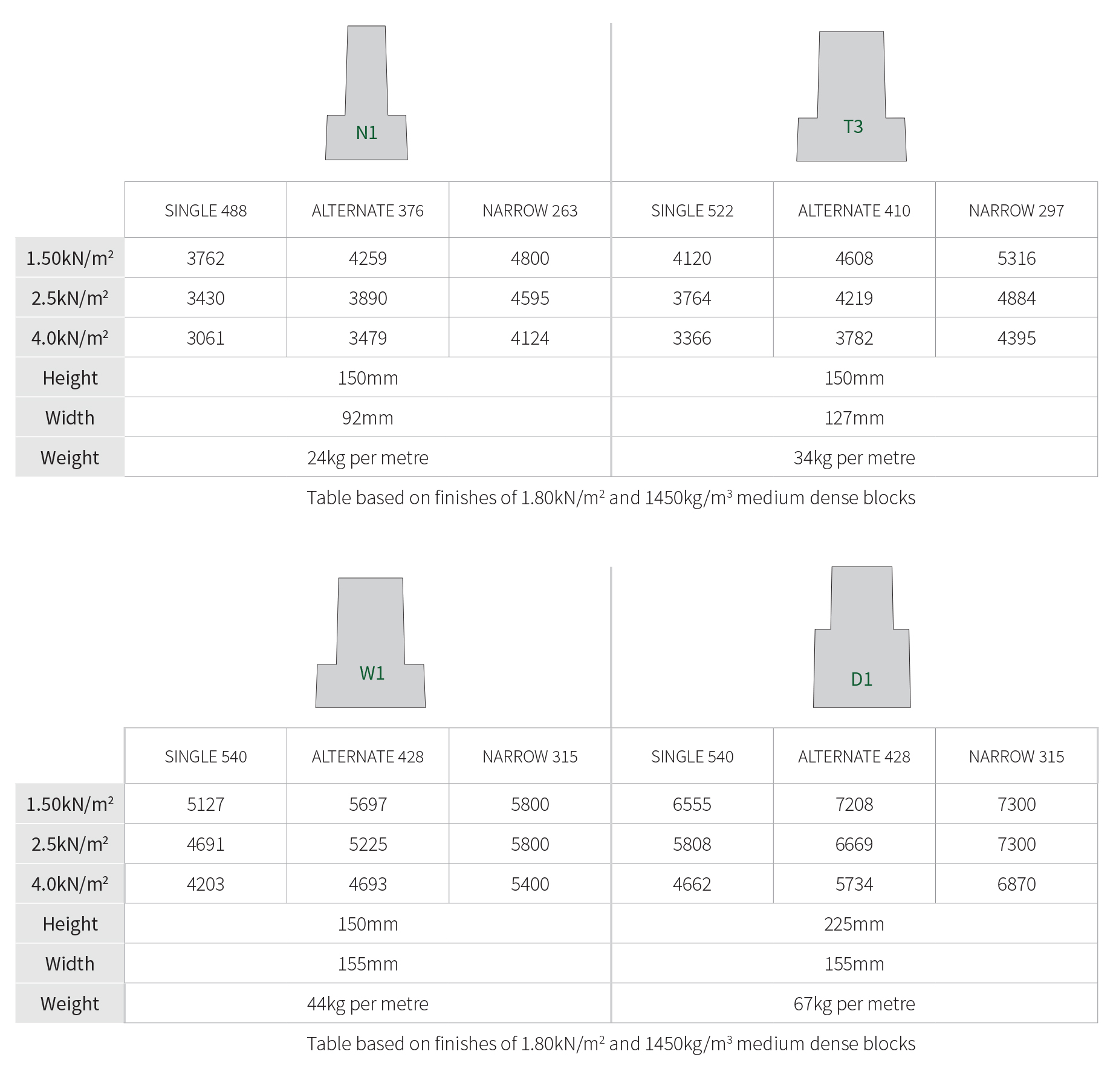

Get in touchCompare our 4 beam types: N1, T3, W1 & D1

With a lightweight profile, our N1 beam can be easily handled in areas with difficult access. Offering a reasonable span, this beam is also well-suited for thermal flooring. Robust and efficient, the T3 beam is used for traditional beam and block flooring and EPS floors. The T3 beam is our highest performance 150mm deep beam and can achieve higher spans than similarly sized beams.

For higher loadings, the D1 beam can span even further and help to reduce foundations costs.

To select the correct beams for your project, speak to a member of our sales team.

Our concrete flooring beams

Wet-cast beams are more operative friendly than extruded beams. With the smooth wet-cast finish, no further work is required on the product.

Extruded beams are commonly left with further maintenance required on the beams by means of removing snots and burrs. This maintenance needs to be done prior to block placing otherwise blocks sit proud/uneven into the floor.

One of the key things to get confirmed early is the block specification for sites. These can often be found on the Architects/Engineer plans and is vital for the pricing element of the project and most importantly the design of the floors.

Each block has it’s own self-weight and guide to where they can and cannot be used. A few examples of universal infill blocks – CEMEX 1400, Lignacite GP, Celcon 3.5N Standard. When a build is getting to digging stage on foundations, the question of blocks must be asked.

Cut to ultra-precise measurements

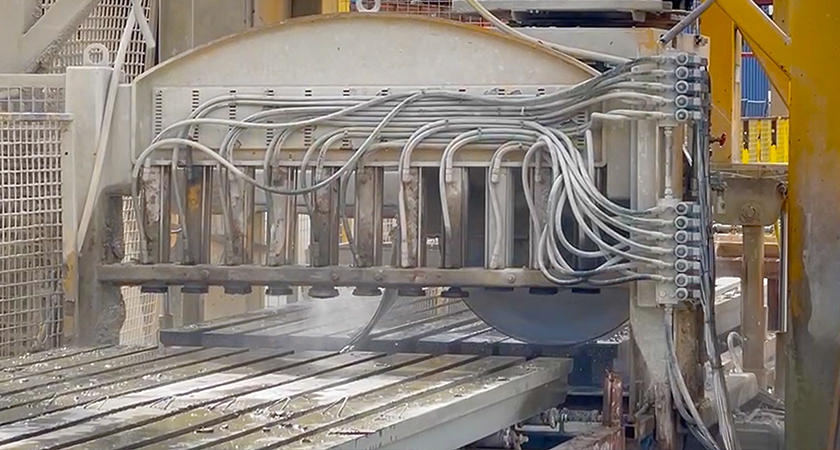

Due to our unique cutting machine – it’s the only one in the country – we can cut 11 beams to different lengths at the same time. This means our production schedules are flexible to tie in with our clients’ demands.

Beams of standard size 30m lengths are cast in our beds. We are then able to provide these beams in various lengths, manufactured to 25mm increments, depending on your requirements. Using infra-red beams for ultra-precise measurements, the 11 beams are arranged to different lengths ready for cutting.

This allows us to turn around your orders quickly.

Contact the beam & block concrete flooring team

If you would like some sales support for your business or branch then please speak to one of the flooring team who would be happy to organise some information to be sent out to you. We can offer branded banners, merchant counter packs with specification sheets for our beams and floor options.

We can also provide training at our factory site for key members of your team to fully understand Beam and Block flooring. Our comprehensive training session will discuss in detail our beam types, demonstrate a beam and block install to help understand the process of how the flooring is installed onto the site and a chance to tour our facility to see how the beams are cast and cut.

Phone us on 01449 723150 or email [email protected]

Get in touch