Poundfield EPS Flooring (PEPS)

Expanded polystyrene (EPS) is proving to be an ideal insulating material in the construction of floors using prestressed concrete beams. PEPS is a lightweight, rigid, plastic foam insulation produced from solid beads of polystyrene. It is made up of 98% air and 2% plastic.

As major manufacturers and suppliers of beam and block flooring Poundfield Precast has introduced PEPS (Poundfield EPS flooring) as a way for our customers to supply more environmentally- friendly solutions to help reduce heating costs by improving thermal insulation and saving wasted energy.

The use of PEPS in conjunction with pre-stressed concrete beams is a highly effective, thermally efficient way of achieving and exceeding the thermal requirements of part L of the building regulations without the need for additional insulation.

PEPS will maintain its performance throughout the lifetime of the building and is therefore a long-term and cost- effective way to reduce heating costs in a property. EPS has obtained an A+ green guide rating.

Poundfield EPS Flooring system can be installed in conjunction with underfloor heating systems which are becoming increasingly popular.

Download the EPS Fact Sheet

What are the benefits of EPS flooring?

- Quick and easy to install

- Cost effective against other block and beam systems

- Can be laid in wet conditions – PEPS is moisture and rot proof

- Reduced wastage as standard sized panels are used for maximum efficiency

- Excellent thermal properties resulting in low thermal conductivity

- A+ green guide rating

- Exceeds the thermal requirements of part L of the building regulations without the need for additional insulation.

- Eliminates the problems associated with part C of the building regulations relating to site preparation and resistance to contaminants and moisture.

- BBA certified number 17/5431 product sheet 2

Frequently asked questions

Is EPS flooring more expensive than traditional block and beam and which is more cost effective?

Depending on the specification of the job, Poundfield’s PEPS system can prove to be more cost effective than traditional beam and block. New planning conditions on floor U-values under Part L results in a reduction in overall floor values from 0.45W/m²K to 0.25W/m²K. We are able to provide full costings and advice on which system will be the optimal solution for your projects.

How do you store PEPS flooring?

The PEPS infill blocks are delivered on 5’ x 4’ pallets and are shrink wrapped. The PEPS infill blocks and top sheet can simply be stored using Herras fencing and weighed down using concrete blocks to prevent them being blown by wind.

Which beams from Poundfield will PEPS work with?

Our PEPS System is compatible with all of our range of beams (N1, T3, W1 and D1).

Does it get damaged by rain?

No. PEPS is waterproof and doesn’t shrink or rot, therefore it can be laid in all weathers without any concerns.

Can you walk on PEPS flooring or will it damage the flooring?

The PEPS system can be walked on after installation within reason, however we do not recommend storing materials or heavy goods on them. Please ensure that your boots are clean before walking on the PEPS to avoid having to clean the blocks before laying the top sheet and membrane.

What grades of PEPS are available?

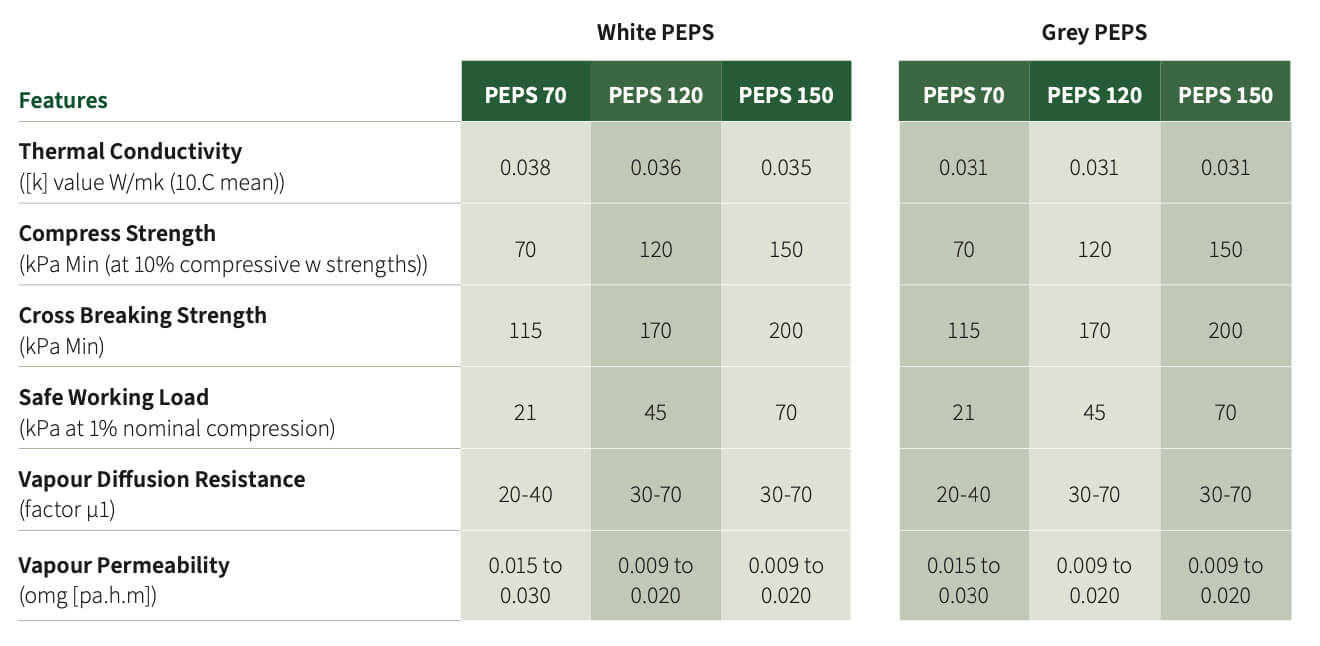

PEPs are available in both white and grey in multiple grades (70/120/150) to achieve your required U-value target. The higher the number, the denser the PEPS, and the better the thermal conductivity. For full details please see the Technical Specifications on the next page.

What is the difference between white and grey PEPS?

The white is our standard option whilst the grey EPS contains tiny chemically modified particles that reflect heat radiation and gives the material its grey colour.

These infrared absorbers and reflectors lower the thermal conductivity of the material offering a thickness reduction of about 20% against standard white EPS.

Download the EPS Fact Sheet

How do you install EPS flooring?

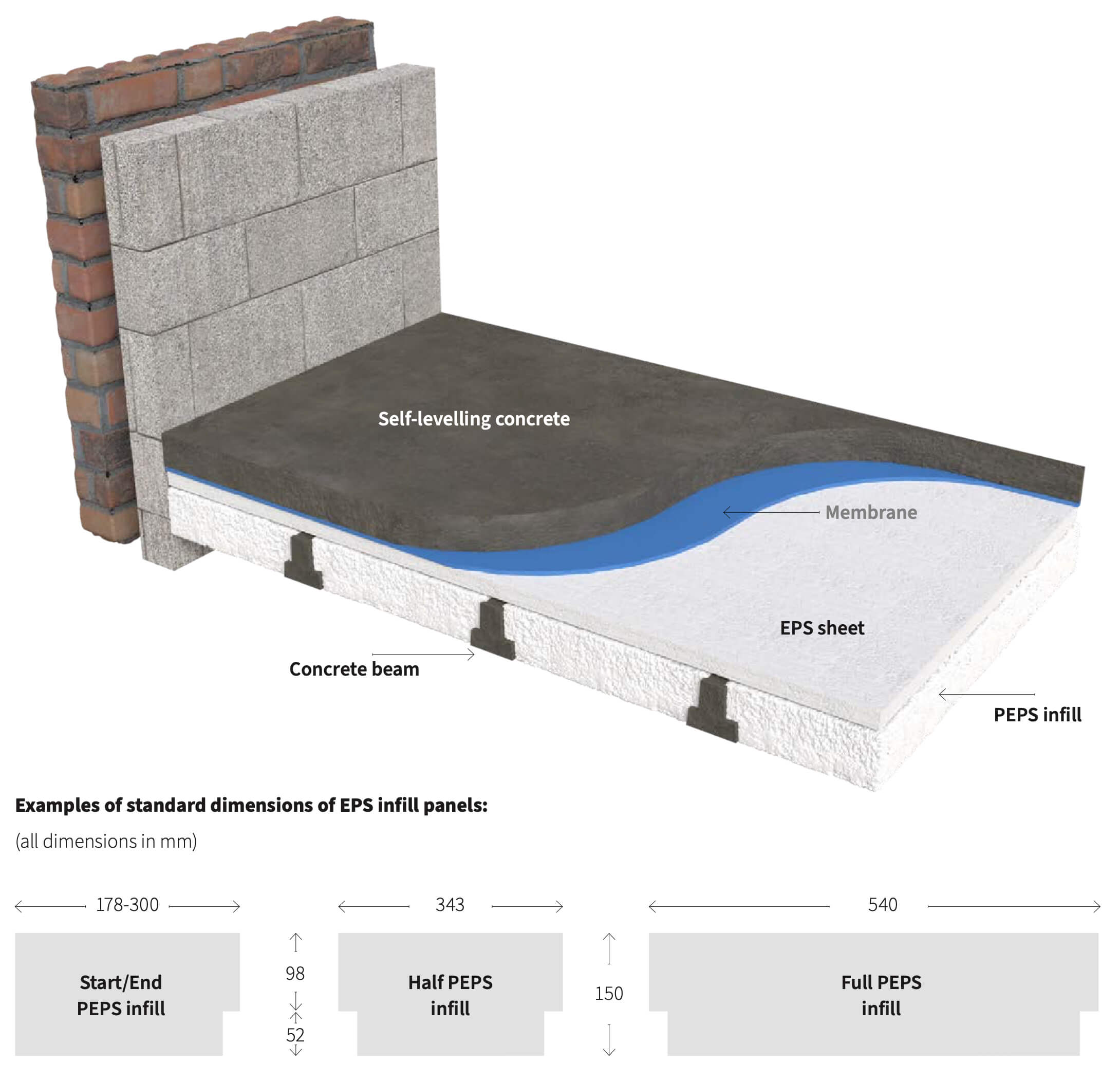

Once the concrete beams have been installed the infill blocks of PEPS are placed in between the beams in much the same way as you would place a concrete block. A top sheet of EPS is then laid on top, followed by a membrane and covered with self-levelling concrete.

Technical specification

Get in touch with our beam & block department

If you have a project that you feel would benefit from the PEPS system or just looking for some advice on cost effectiveness, feel free to contact us on 01449 723150 or [email protected]

Get in touch