Flexible retaining wall solutions at Sackers Recycling

Posted on: February 15th 2018 • Posted in: Betaloc, Case studies, Industries, Retaining Walls, Waste & Recycling

Sackers Recycling is a family-run business which specialises in the recycling of scrap metal, commercial and industrial waste. Operating from two sites near Ipswich they required a flexible storage solution to cater to the growing demands of their business and the waste that they handle.

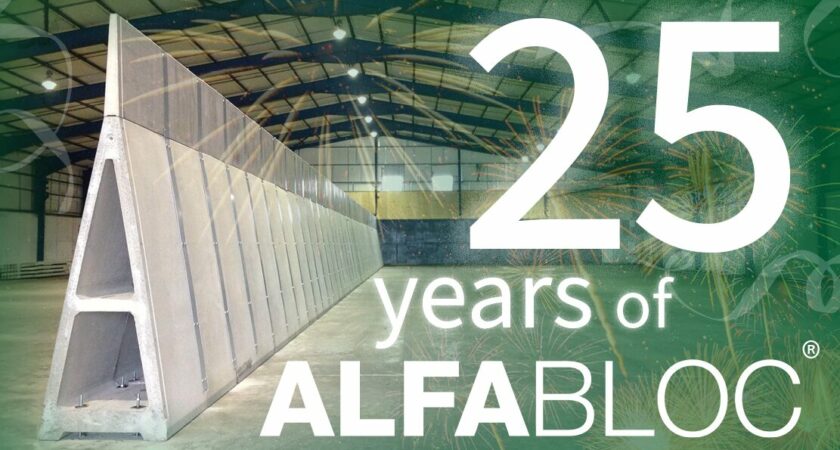

Processing large volumes of varying types of waste Sackers have worked with Poundfield Precast over the years to develop storage systems which could easily grow with the business. For permanent bays, they have used a mixture of Alfablocs and prestressed panels. In addition, Sackers have relied on Betaloc XL concrete blocks where they wanted to be able to reconfigure the size of bays easily and quickly.

Betaloc Blocks allow for easy reconfiguration

“We like the flexibility of the Betaloc blocks as it allows us to reconfigure the bays as our needs change. The blocks weigh in at around 2.4 tonnes each and therefore they provide a robust dividing wall which can be loaded on both sides,” said Adrian Dodds, Director for Sackers.

A dividing wall can be created quickly and easily thanks to the interlocking design of the Betalocs. They can be stacked up to 3 high giving a total height of 2.4 metres. The Betabloc blocks can be removed and relocated at any time making them suitable for both temporary and permanent structures.

“Perfect for constructing storage areas, dividing walls, perimeter or retaining walls, Poundfield Precast’ block by block design allows customers to design a wall specific to their requirements and allows complete freedom to modify or expand the system in the future,” said Matt Moss, Commercial Director for Poundfield Precast.

“Keeping product separated is increasingly becoming more important in the waste industry, especially to avoid the risk of cross-contamination once the waste has been sorted,” said Mr Dodds.

“An efficient storage system is vital to us as a business and the Betaloc blocks gives us the flexibility we need as our business grows and the volumes we handle increase”.

Photos from Sackers Recycling

Click to expand each photo.

[acfgallery]