Poundfield Precast achieve important fire certification

Posted on: October 11th 2018 • Posted in: Industries, Waste & Recycling

Back in May, our precast concrete underwent fire resistance testing. The results are back, and we’re proud to announce that we passed with flying colours!

Tested by warringtonfire, a world leader in the provision of fire safety services, this certification is a globally respected mark of quality assurance. Certified in accordance with BS476: Part 22, you can rest assured that our concrete has been tested to the most vigorous of standards.

How was Poundfield concrete fire tested?

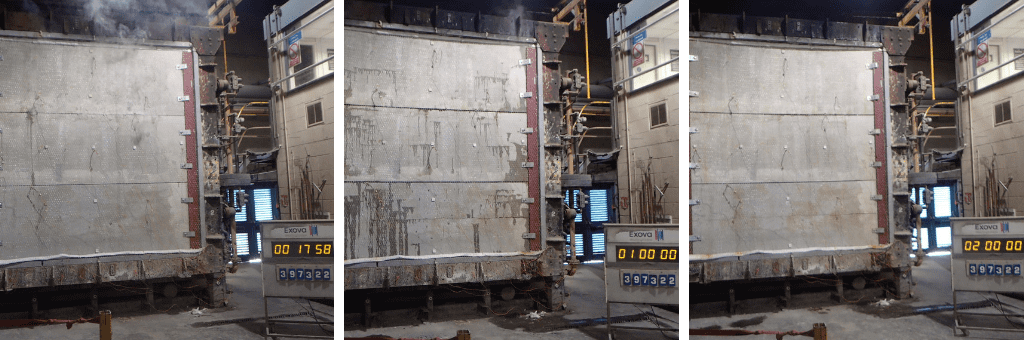

For the purposes of this test, three interlocking concrete panels were subjected to extremely high temperatures for a prolonged period of time.

The specimen piece used was 3035 x 3000 mm with a thickness of 100 mm.

Tested to replicate the product’s end use – in this case as a non-loadbearing wall – the specimen unit was built into a restraint frame and mounted onto the front of a temperature-controlled furnace.

Heated to represent a post-flashover condition, where every exposed surface in a space reaches its autoignition temperature, the test took place for over two hours.

With temperatures reaching in excess of 1000°C, the integrity of the product was proven. Thermocouples measured the temperature of the outer surface, while cotton pads and gap gauges were available to evaluate the impermeability of the specimen to hot gases.

To satisfy the requirements of the test, it was required that there was no collapse, sustained flaming on the unexposed surface, or loss of impermeability. It was also required that the unexposed surface did not suffer a mean temperature rise greater than 140° or a maximum rise greater than 180°.

These requirements were all satisfied for 132 minutes, confirming our concrete’s excellent fire-resistant properties.

What does this mean for our customers?

Concrete is well known for being non-combustible. With a slow rate of heat transfer, one side of the concrete can remain relatively cool, while the other is exposed to extreme heat.

This certification proves that our concrete panels maintain their integrity and insulation following exposure to extreme heat.

Not every supplier produces concrete panels to this specification, but our customers can rest assured that our precast concrete products have met this important certification standard.

Precast concrete is especially effective in the waste and recycling industry

Resistance to fire is especially important in the building and waste & recycling industries, where the potential for spontaneous combustion is great.

Between 2001 and 2013 there were, on average, more than 300 fires at waste & recycling plants in the UK. Posing a risk to life and buildings, fires can be devastating for businesses in this sector. The use of wooden sleepers is commonplace, but these tests confirm that for increased fire resistance, concrete from Poundfield is certainly the more suitable material.

To find out more about our range of precast concrete retaining walls for the waste & recycling industries, please call us on 01449 723150 or email [email protected].